Advantages of Blue-White Peristaltic Metering Pumps

Today’s commercial swimming pools have a plethora of pumps and heavy machinery in their equipment rooms to ensure efficient maintenance. Chief among this pool equipment are chemical feeders. Properly balanced water chemistry is essential for the health and safety of not only your guests, but also your aquatics facility. In addition to chemical controllers and water testing equipment, you will want to make sure that your pool has the best chemical metering pump.

Chemical metering pumps offered by Blue-White are peristaltic pumps, which use rotary motion to move the fluid through tubing. These kinds of chemical metering pumps are precise and ideal for moving sterile or aggressive chemicals because they limit contamination as the chemical moves through the pump. All peristaltic chemical metering pumps from Blue White are self-priming, even against maximum line pressure. And, by-pass valves are not required since peristaltic pumps cannot experience the vapor lock caused by off-gassing, a common problem for diaphragm pumps.

Off-gassing occurs when liquid chlorine aerated by the action of pumping creates bubbles that transfer to the inner walls of the diaphragmatic pump and valves. This creates an air lock that impedes fluid from flowing through the pump, even if the pump appears to be functioning normally. Peristaltic pumps do not expereince this issue due to their rotary design, which moves the liquid via compression of the tube and the pushing motion of the rollers.

Blue-White Offers Two Peristaltic Chemical Metering Pumps Models

- For small to medium pools, Recreonics recommends Blue-White’s A100N Flex-Flo chemical metering pump. This model has the capacity to pump 3.96 GPH-24 GPD at pressure up to 100 PSI or 95.1 GPD up to 50 PSI. The A100N has a standard solid-state output adjustment in a 60 second cycle. Tubing size may vary depending on your needs and the flow rate your facility requires, but the end connection of all tubes is a 3/8-inch compression fitting. The A100N Flex-Flo pump features a 20:1 turndown ratio.

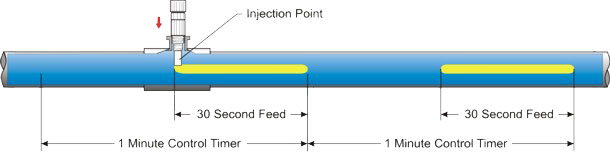

Control the feed of chemicals from the A100N by using timers. The chemical or solution is mixed in the water. This graphical representation of the fixed speed peristaltic pump injection is only illustrating the feed characteristics. - Blue-White’s A2P Flex-Pro chemical metering pump is perfect for large commercial swimming pools and water parks. This newly introduced peristaltic metering pump offers feed rates up to 15.9 GPH, or 381 GPD, at a pressure of up to 50 PSI. The A2P Flex-Pro pumps use the dual-channel Flex-A-Prene Tubing which produces 4 times the lifespan of the regular single-channel tubing. This allows the pump to work efficiently in high-volume aquatic facilities, like water parks, which circulate several hundred thousand gallons of water. The A20 Flex-Pro pump features a 100:1 turndown ratio and can be more fine-tuned than the A100N pump for precise chemical flow into larger pools.

A100N Flex-Flo and A2P Flex-Pro chemical metering pumps both feature a precise output control adjustment knob on the front of the pump, allowing you to manually adjust the chemical output from the pump. However, for specific programming, chemical measuring, and other functions you will need to pair your pump with a chemical controller. The chemical metering pump itself functions more like an on-and-off switch when it comes to chemical feed.

Blue-White Patented Tube Failure Detection System (TFD)

A100N Flex-Flo and A2P Flex-Pro chemical metering pump models both feature Blue-White’s patented Tube Failure Detection System (TFD). While all tubing supplied with these pumps are chemically resistant, friction from the rotary motion could wear on the tubing, causing eventual ruptures or failures. The TFD System will detect a wide range of conductive chemicals with no false triggering. If the TFD senses a tube failure, the pump will automatically shut off and energize a relay or switch, permitting communication with any external equipment, such as a back-up pump or alarm your facility may have.

BA100N Flex-Flo and A2P Flex-Pro Chemical Metering Pumps Maintenance

The simple and efficient design of peristaltic chemical metering pumps makes maintenance easy. To clean, simply open the NEMA enclosure, making sure the pump is turned off, and remove the tubing by turning the pump slowly to help feed the tube out. Clean the inside and the roller with a degreaser, then reinsert the tube the same way it was removed. While cleaning is easy, you will want to regularly replace the tubes and lubricate the rollers. Periodically check the rollers to make sure they are not frozen and are rolling correctly, as this kind of motor behavior can dramatically shorten the life of your pump.

Blue-White’s peristaltic chemical metering pumps are the perfect pump for any swimming pool, large or small. Combining the proven peristaltic technology with a patented Tube Failure Detection system makes Blue-White efficient and reliable for high-volume aquatics facilities as well as neighborhood swimming pools and spas.